i.tech are highly technological products, able to guarantee ultra-high performance in terms of strength and safety.

![]()

i.tech ALI CEM

|

|

|

|

| Also for renewal Rapid setting, Mechanical Strength, Shrinkage control | Innovative product Environmental & product performance | Product Sustainable CO2 Output: 665 kg/t, Recycled Materials: 506 kg/t |

i.tech ALI PRE combines excellent environmental process perfomance to local raw materials use.

For the first time, the environmental performance do not limit the product performance which, in the case of i.tech ALI CEM, are at the top of the cementitious binders both in terms of absolute values and of consistency.

In addition, the calcium sulfate used, is micronized in a dedicated plant and later on blended with i.tech ALI PRE. This phase, together with an effective and sophisitcated control and dosage process, position i.tech ALI Cem at the top in terms of qualitative consistency.

Field of use & Characteristics

When mixed with calcium sulfate and Portland cement, i.tech ALI PRE is particularly suitable to formulate:

• Rapid technical mortars (for repairs, fixing clamps, etc.)

• Rapid and semirapid pourable mortars

• Sprayed mortars and shotcrete

• Low shrinkage mortars

• Joints mortars

• Rapid and semirapid floor screeds

• Self levelling rapid floor screeds

• Rapid sealants

i.tech ALI PRE has the main following characteristics:

• Possibility to change the setting time in a very wide time interval by varying the mixing ratios between i.tech ALI PRE, Portland cement and calcium sulphate

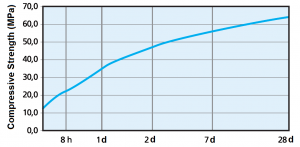

• Rapid early strength development

• Progressive strength development at medium and long term

• Shrinkage control

Chemical & Physical Properties

| Soundness | ≤ 10 |

| Initial Setting Time (min) | ≤ 25 |

| Fineness – Sp. Surface Area Blaine (cm2/g) | 5 000 +/- 500 |

Hydration products

![]()

i.tech ALI PRE

|

|

|

|

| Also for renewal Rapid setting, Mechanical Strength, Shrinkage control | Innovative product Environmental & product performance | Product Sustainable CO2 Output: 738 kg/t, Recycled Materials: 603 kg/t |

Here below some relevant environmental performance:

CO2 Emissions equalt to 738 kg CO2 / t

Content of recycled materials equal to 603 kg / t

i.tech ALI PRE combines excellent environmental process perfomance to local raw materials use.

For the first time, the environmental perfomarnce do not limit the product performance which, in the case of i.tech ALI PRE, are at the top of the cementitious binders both in terms of absolute values and of consistency.

Field of use & CharacteristicsWhen mixed with calcium sulfate and Portland cement, i.tech ALI PRE is particularly suitable to formulate:

• Rapid technical mortars (for repairs, fixing clamps, etc.)

• Rapid and semirapid pourable mortars

• Sprayed mortars and shotcrete

• Low shrinkage mortars

• Joints mortars

• Rapid and semirapid floor screeds

• Self levelling rapid floor screeds

• Rapid sealants

i.tech ALI PRE has the main following characteristics:

• Possibility to change the setting time in a very wide time interval by varying the mixing ratios between i.tech ALI PRE, Portland cement and calcium sulphate

• Rapid early strength development

• Progressive strength development at medium and long term

• Shrinkage control

Alcune delle performance ambientali più siginificative:

| Emissioni di CO2 (Global warming potential) | 738 kg CO2 / t |

| Contenuto di materiale riciclato | 603 kg / t |

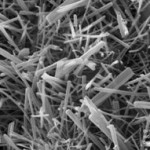

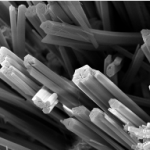

Hydration products

|

|

| Ettringite Crystals (20.000 X) – Ettringite Crystals (60.000 X) | |

Main Phases

| C4A3$ | C2S | C$ |

| ≥ 58 | ≤ 25 | ≤ 5 |

C = CaO; A = Al2O3; S = SiO2; $ = SO3

Main Chemical Components

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO |

| 36 ÷ 41 | ≤ 9 | 27 ÷ 33 | ≤ 1.5 | 10 ÷ 14 | ≤ 5.0 |

Fineness

| Specific Surface Area Blaine (cm2/g) | 4 750 +/- 250 |

![]()

i.tech CARGO

|

|

| Innovative product Highly percolating slurry for easy placing | Sustainable product Improve the lifespan of pavements |

Less maintenance

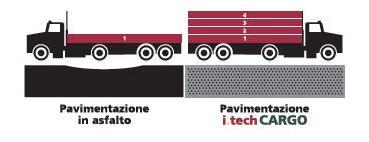

Compared to traditional asphalt pavement, i.tech CARGO eliminates such phenomena as rutting and wear while ensuring enhanced durability and reduced ordinary maintenance costs.

Sustainability i.tech CARGO makes less use of bituminous binders and associated polluting oils. Moreover, thanks to its bright colored surface (albedo effect), i.tech CARGO reduces the pavement’s temperature and improves comfort.

Greater safety Pavement surfaces made with i.tech CARGO, either bushhammered or shot-blasted, can offer excellent traffic flow performance. What’s more, the jointless overlay guarantees driving safety and comfort.

High heat resistance A special cementitious matrix makes i.tech CARGO definitely more resistant to high temperatures than the traditional asphalt-based solutions. i.tech CARGO contributes to promoting safety as it does not undergo the traditional heat deformation phenomena.

Pigmentable Any pavement made with i.tech CARGO can be custom-made at the building site by adding natural pigments that give the mix a smooth homogeneous colour

|

Benefits • Up to 4 times stronger • Enhanced strength • Smaller thickness • Resistant to peak loads • Resistant to high temperatures • Resistant to chemical attack • Resistant to wear • Easy to install • Cuts maintenance costs • Reduces surface temperatures • No need for joints • Enhanced comfort |

| Main applications • Road and highway tunnels • Road sections subjected to heavy vehicle traffic • Heavy duty and industrial pavements • Freight villages • Airport areas • Stocking warehouses • Logistic areas • Parking areas for special vehicles • Parking areas for shopping centers • Highway toll booth lanes • Tram and bus stop lanes • Manoeuvre areas for military equipment |

|

![]()